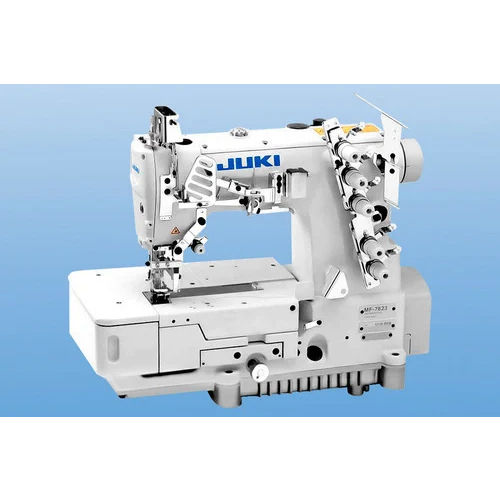

Juki Flatlock Sewing Machine

Price 88000 INR/ Unit

Juki Flatlock Sewing Machine Specification

- Needle

- UY128GAS

- Operate Method

- Automatic

- Sewing Speed

- Up to 6000 SPM

- Stitch Length

- 1.0mm - 4.0mm

- Voltage

- 220V / 240V

- Warranty

- 1 Year

- Sewing Thickness

- Medium to Heavy

- Feed Mechanism

- Differential Feed

- Product Type

- Juki Flatlock Sewing Machine

- Condition

- New

- Stitch Formation

- Flatlock

- Power

- 400W

- Stitch width

- 3.2mm - 6.4mm

- Color

- White

- Dimension (L*W*H)

- 580mm x 250mm x 530mm (approx.)

- Bed Type

- Flat Bed

- Weight

- 34 kg (approx.)

- Lubrication

- Automatic Lubrication System

- Application

- Industrial garment production, especially for sportswear & underwear

- Noise Level

- Low-vibration, low-noise design

- Thread Type

- 3/4 Thread

Juki Flatlock Sewing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 30 Units Per Month

- Delivery Time

- 20-25 Days

- Main Domestic Market

- All India

About Juki Flatlock Sewing Machine

Precision Stitching Meets Industrial Demands

The Juki Flatlock Sewing Machine excels in the production of high-performance sportswear and underwear. Its flatlock stitch formation guarantees strong, flat seams, ensuring both comfort and durability in garments. With an automatic lubrication system and efficient thread handling, its built to withstand continuous operation in busy manufacturing settings.

Engineered for Operator Efficiency

Featuring an automatic operating method and an ergonomic flat-bed design, this machine supports productivity while minimizing fatigue. Its low-vibration, low-noise engineering creates a comfortable workspace, even during long hours. The differential feed mechanism prevents fabric puckering or stretching, delivering consistently professional results on medium to heavy textiles.

FAQs of Juki Flatlock Sewing Machine:

Q: How does the automatic lubrication system benefit the Juki Flatlock Sewing Machine?

A: The automatic lubrication system keeps all internal components properly oiled during operation, reducing maintenance needs and prolonging machine life. This ensures smooth and continuous stitching, essential in industrial garment production environments.Q: What types of garments are best suited for this flatlock sewing machine?

A: This machine is particularly well-suited for industrial production of sportswear and underwear, thanks to its flatlock stitch formation, which provides strong, flat seams ideal for stretchy or fitted garments.Q: When should I consider adjusting the stitch width or length on this machine?

A: You should adjust the stitch width (3.2mm to 6.4mm) and length (1.0mm to 4.0mm) based on the type of fabric and the required seam finish. For thicker fabrics or for a wider, more prominent seam, use a wider stitch. Shorter stitches are generally used for finer fabrics or detailed work.Q: Where can I purchase or service the Juki Flatlock Sewing Machine in India?

A: This machine is available through authorized distributors, manufacturers, service providers, suppliers, and traders throughout India. After-sales service and warranty support are also provided by these partners.Q: What is the process for threading the Juki 3/4 Thread Flatlock Sewing Machine?

A: Threading involves following the designated threading paths as outlined in the user manual, ensuring each of the 3 or 4 threads is correctly passed through tension discs, guides, and the UY128GAS needles. Proper threading is essential for consistent flatlock stitching.Q: How does the differential feed mechanism contribute to better stitching?

A: The differential feed mechanism allows independent adjustment of the front and rear feed dogs, preventing fabric stretching or puckering. This is especially useful when sewing stretchy or layered textiles, ensuring smooth, even seams.Q: What are the advantages of the flat-bed design and low-noise operation in an industrial environment?

A: The flat-bed design makes fabric handling easier and more stable, which is especially useful for larger or bulky items. Low-noise, low-vibration operation creates a more comfortable and less fatiguing work environment for operators during extended production runs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Sewing Machine Category

Juki Ddl 8100e Sewing Machine With Direct Drive Motor

Price 24000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : White

Condition : New

Product Type : Juki Ddl 8100e Sewing Machine With Direct Drive Motor

Warranty : 1 Year

High Speed Overlock Sewing Machine

Price 24500 INR / Unit

Minimum Order Quantity : 1 Unit

Color : White

Condition : New

Product Type : High Speed Overlock Sewing Machine

Warranty : 1 Year

Super High Speed Overlock Sewing Machine

Price 23000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : White

Condition : New

Product Type : Super High Speed Overlock Sewing Machine

Warranty : 1 Year

Juki Hzl 29Z Automatic Sewing Machine

Price 12000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : White

Condition : New

Product Type : Juki Hzl 29Z Automatic Sewing Machine

Warranty : 1 Year

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS